木材优选锯

Optimizing Cross-cut Saw

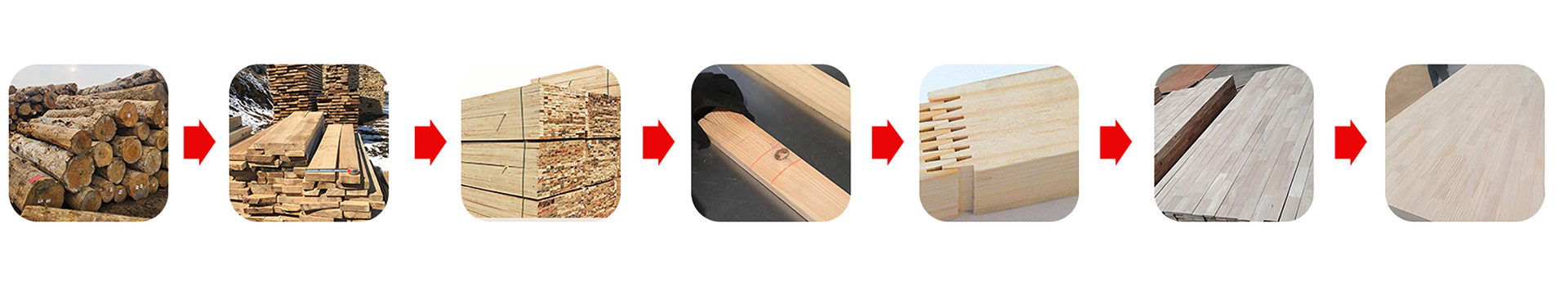

此款木材优选锯,主要应用于木材加工厂、家具厂的备料。采用德国西克检测系统,机器前端,配有划线台,工人只需要在木条疤节的位置划线标记,机器便会自动对线条进行识别,并准确地进行截断。它能根据设置的尺寸,对无缺陷的部分,进行优化组合并锯切,提高木材出材率和生产效率。

This wood optimized saw is mainly used in wood processing plants and furniture factories for material preparation. The equipment adopts the German Sick detection system. The front end of the machine is equipped with a marking table, and the worker only needs to mark the position of the strip scar, and the machine will automatically identify the line and accurately cut it off. It can optimize the combination and sawing of the non-defective parts according to the set size, improving the wood yield and production efficiency.

人工远离锯片,安全无风险。

Workers can move away from the saw blade for safe, risk-free operations.

该设备采用30度倾斜的输送方式,高品质进口同步带传动,保证了锯切的高精度。每分钟200米的进料速度,是当前中国产量最高、精度最高、速度最高的优选锯。 锯切掉的废料自动进入锯口后侧的废料通道,轻松输出并收集。该设备采用高性能进口伺服电机及控制系统,运行稳定速度快,反应敏捷,运算精准。机器出料输送台,配有多个分选踢腿。可以将不同长度的木条进行精准分类,省掉人工,提高工作效率。

The equipment adopts a 30 degree inclined transmission mode. The high quality feed port can synchronize the belt drive to ensure the high precision of sawing. With a feed speed of 200 meters per minute, it is currently the Optimizing Cross-cut Saw with the highest output, highest precision and highest speed in China. The sawn waste automatically enters the waste channel on the back side of the saw for easy output and collection. The equipment adopts high-performance imported servo motor and control system, which can not only run stably, fast, but also respond quickly and calculate accurately. The machine discharge conveyor is equipped with a number of sorting kicks legs, which can accurately classify wood strips of different lengths, so it saves labor and improves work efficiency.